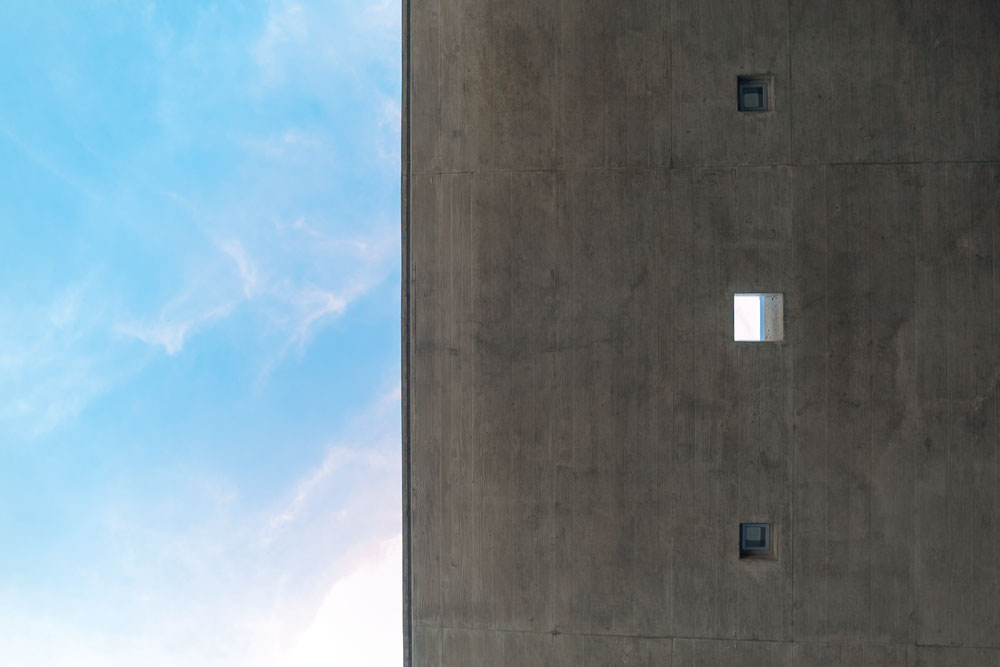

The waterproofing of the large podium of a Brutalist building can only be in fair-faced waterproof concrete.

Domus Adriana was born in the seemingly narrow path of physical and architectural limitations and, like a stream in a gorge, it is precisely from obstacles that it draws energy and meaning.

A project designed by constraints.

Like the land located 9 meters above the street level, an existing building in grey concrete with which to communicate and, again, the absence of surface access to the road.

The architect Edy Quaglia has in fact decided to design a free form, which refers only to its own volume. A monolith characterized by an empty entrance, which connects the entire volume with the street below.

The clients of the work are the owners of the Taddei di Viganello construction company. Domus Adriana was therefore required to also be an expression of their professional quality and their passion.

In this sense, facing concrete is the most effective choice, because it literally leaves the builder’s work bare, showing his skill and care without filters.

However, the proximity of another concrete building presented a context problem, which in turn proved to be a powerful opportunity.

To mark the gap between the two buildings, the concrete was in fact colored red and, consequently, rough formworks were used, laid horizontally.

In addition to defining the identity of Domus Andriana, this choice has enhanced the dialogue between the two buildings.

The coloring and horizontal formwork also characterize the space between the volumes and, in particular, the elevator walls and open stairways.

An architectural continuity that brings out the idea that the void separates the two volumes of the building, but formally unites them, emphasizing the fixed scene.

Domus Adriana is spread over seven floors, three of which are completely underground and four resting on the natural ground, divided into apartments.

The hypogeum is a waterproof structure made with a 1,540 m² Drytech Tank, which houses cellars and laundries for each apartment, the technical rooms and two garages with direct access to the street.

Owners: Fulvio and Adriana Pagnamenta, Cureglia

Project: Architetto Edy Quaglia, Lugano

Structure: Ing. Fulvio Pagnamenta, Cureglia

Construction: Taddei, Viganello

Drytech Tank: 1,540 m²

Photos: L. Crivelli, A. Vitiello, G. Pagnamenta