Drytech Tank

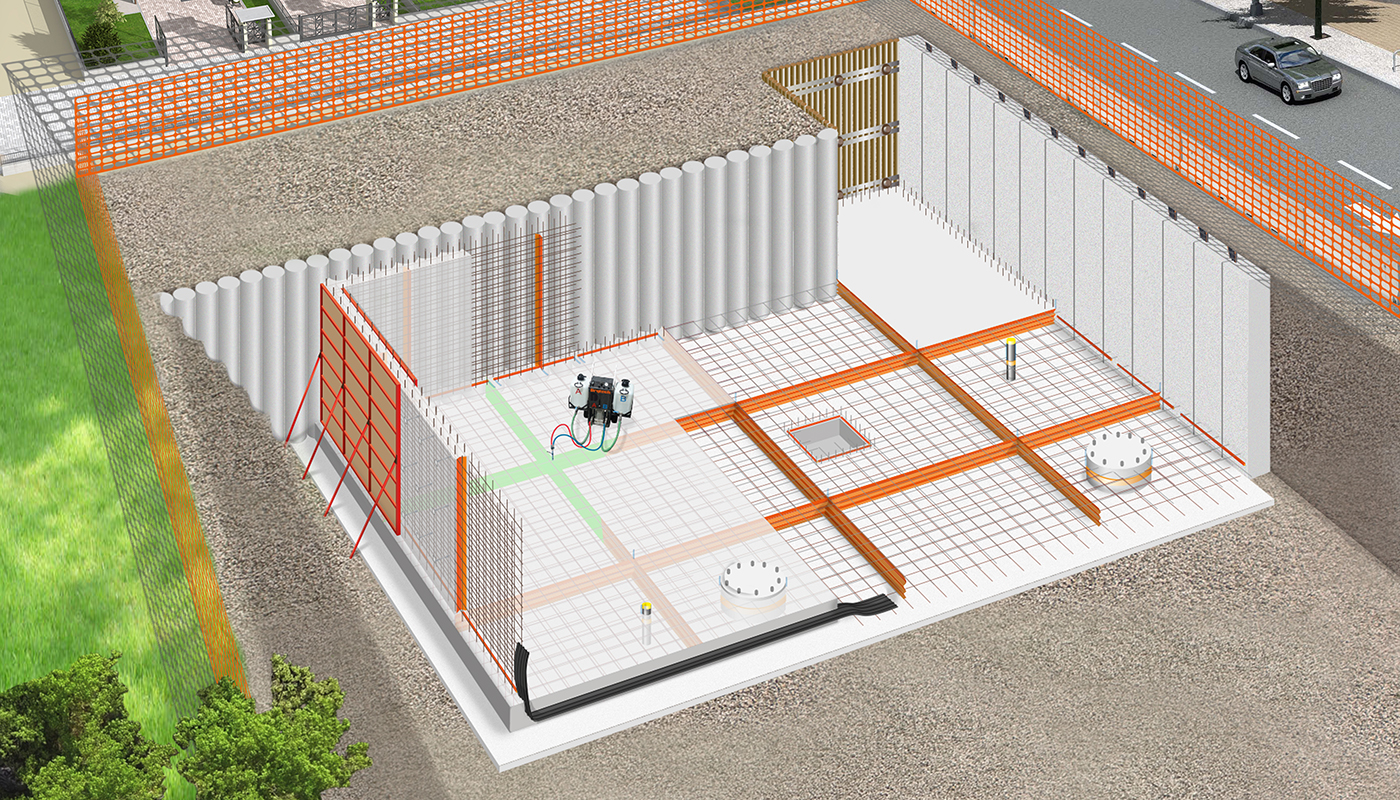

The Drytech Tank is the structural waterproofing

for underground constructions, in groundwater or in contact with liquids.

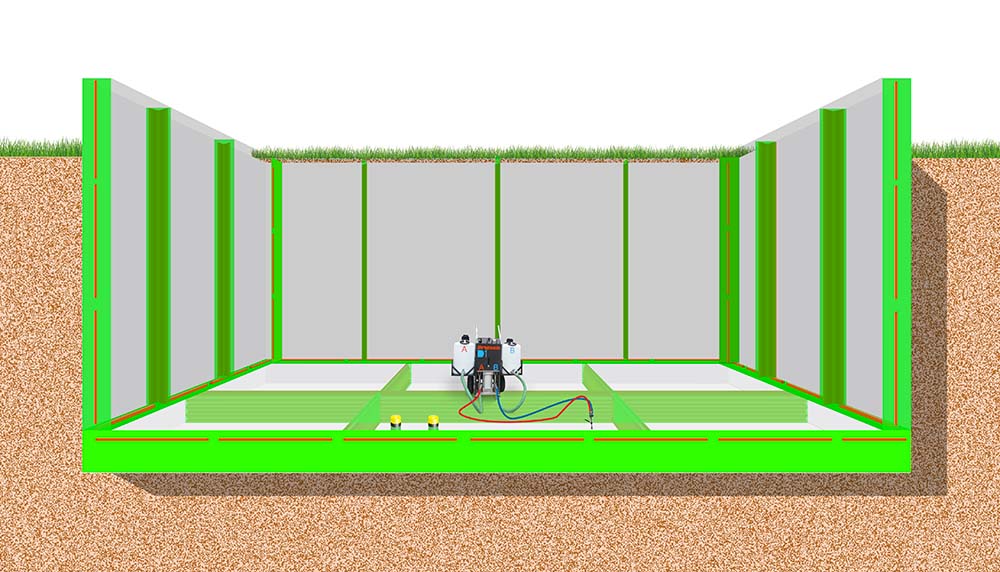

It is a single structure in waterproof concrete

with the construction details sealed by expanding acrylic resin.

The entire surface and entire thickness of the structure are waterproof.

Construction is quick and convenient for everyone.

Waterproofing is integral, solid and guaranteed.

The Drytech Tank guarantees:

- the tightness of the structural waterproofing, which opposes the ingress water and radon creating a barrier equal to the thickness of the structure itself;

- the saving of time and related costs for the entire construction site, easily quantified with the cancellation the waterproofing item from the Gantt chart;

- the security of the Drytech Engineering’s continuous consultancy to the designer and the construction company;

- the real possibility of maintenance of the below grade structure, for the entire life cycle of the building.

DRYTECH waterproof CONCRETE

Drytech Engineering creates the tailored mix design for the specific construction

based on the characteristics of the concrete plant chosen by the client.

Drytech concrete has two characteristics: it prevents the penetration of water and reduces the formation of cracks.

Cracking is an inevitable phenomenon of maturation, but the Drytech Tank manages and controls it.

The Drytech Recipe is aimed at obtaining a progressively maturing concrete that, in combination with the DRYset cracking elements, tends to avoid the formation of random cracks.

Drytech Engineering adapts the formula to the characteristics of the concrete plant chosen by the customer, without additional costs and without additives.

Drytech performs quality checks at the concrete plant, on site and in the laboratory, to transfer all the waterproof qualities defined in the formula specific to the structure.

WATERPROOF construction DETAILS

The components of the DRYset program prepare the details to ensure a rapid and capillary diffusion of the DRYflex resin, which waterproofs the details throughout the thickness of the structure.

DRYset channels, sleeves and crack inducing elements are installed by Drytech technicians without affecting the work schedule and regardless of the weather, because the DRYset elements are made of materials that do not react to water.

The DRYset sleeve predisposes the crossing to the rapid and capillary diffusion of the waterproofing resin.

The system is suitable for penetrations of any type and size.

The installation is independent of the weather and parallel to the other activities of the construction site.

Once its function has been exhausted, the DRYset Pump Well is incorporated into the bed and waterproofed both externally and internally:

> the outside of the well in contact with the slab is injected with DRYflex expanding resin, which seals the element throughout the thickness of the structure.

> the inside of the well is sealed by the lid equipped with gaskets both on the circumference of the well and on each of the sealing bolts.

The DRYset Waterproof Pump Well can be equipped with a lid with a shutter, which makes it inspectable, and a pressure gauge to monitor the pressure of the aquifer.

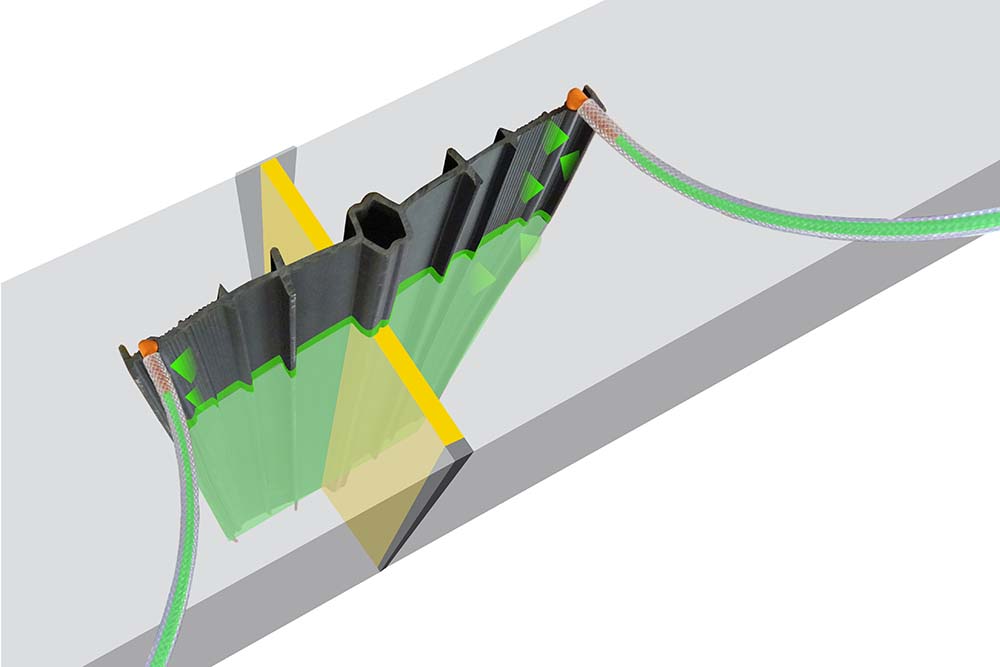

The DRYset Channel predisposes the cold joint for rapid and capillary diffusion of the waterproofing resin.

The system is suitable for joints of any type and size.

The installation is independent of the weather and parallel to other activities of the construction site.

The movement joints are waterproofed with DRYset Injectable Waterstop Tapes.

In addition to prolonging the path of the water, DRYset Waterstops allow you to completely inject the movement joint with the DRYflex expansive resin, which spreads through micro-perforated ducts integrated into the tape itself.

Any maintenance re-injections are simple and non-invasive.

The system is suitable for motion joints of any size.

The diaphragms can be made directly waterproof with the insertion of DRYset Injectable Waterstop Tapes in the joints between the septa.

The waterproofing of the diaphragm overcomes the need for waterproof walls to cover.

It is a solution that is adopted for example in basements where the volume must be exploited to the maximum, for regulatory or economic reasons.

The special DRYset Waterstops for diaphragms are equipped with micro-perforated cannulas – accessible from inside the structure – to inject the entire thickness of the joint with DRYflex expanding resin.

Furthermore, the system allows maintenance re-injections in the face of any infiltrations.

The formwork holes are sealed with the insertion of a pressure cap and the application of DRYpox epoxy resin.

Waterproofing injections

The construction details are waterproofed with the injections of DRYflex Expanding Resin: the two-component acrylic resin that seals joints, cracks and penetrations by pressure, throughout the thickness of the structure.

The DRYflex Resin and Drytech Waterproof Concrete form a waterproof barrier that has exactly the same thickness as the basement, because structure and waterproofing coincide: the structure is the waterproofing.

At the time of injection DRYflex has a viscosity similar to water and, like water, takes the shape of the void it saturates: from microporosity to the gravel nest.

After a few moments it catalyzes, turning into an expanding gel that seals the detail by pressure (not by adhesion!).

The tightness of the waterproofing can be checked with the naked eye from inside the structure.

Drytech Engineering

DESIGN. CONSULTING. SHARING.

Designing waterproofing reduces costs and increases quality: over 83% of infiltration problems are caused by design errors (EMPA Research 2004, report 210043 – 202248).

Drytech shares its specialization and experience with architects, engineers and construction companies to design and build together strong, affordable and guaranteed waterproofing.

Drytech Engineering assists and supports the Structural Engineer in the design of the Waterproof Structure, optimizing the construction choices according to watertight.

Drytech Engineering also supports the company in the state-of-the-art construction of the Drytech tank.

This collaboration transfers into your project the solutions and experience of 1,000+ construction projects built every year throughout Europe, from dams to parking lots, from basements to swimming pools, from cisterns to aqueducts, including small private cellars.

A specialized support that reduces costs and construction times and guarantees the efficiency of the waterproof structure, no matter its size.

design

- Engineering consultancy for the design of the underground structure.

PREQUALIFICATION

- Pre-qualification of Drytech Waterproof Concrete in the plant indicated by the customer.

Controlling

- Control of rebar steel plan in anti-shrinkage function.

- Quality checks on concrete on site and in the laboratory.

- Checks laying rebar and concrete casting.

- Advice to the company for the state-of-the-art construction of the underground structure.

QUALITY AND MAINTENANCE

- Quality and maintenance dossier with protocols, photos and installation plans for DRYset systems.

- It’s the X-ray picture of the Drytech Tank, that is also useful for accurately drive any maintenance interventions even after years.

- The Quality Dossier can also be made in digital format with the ability to virtually navigate within the structure.

WATERPROOF GUARANTEE

GUARANTEE

The waterproofing of the Drytech Tank structures is covered by the Ten-Year Warranty, which can be further extended with a maintenance contract.

MAINTENANCE

Would you buy a car whose wheel cannot be replaced in the event of a puncture? A waterproofing system that does not provide or, worse, does not allow maintenance is like a disposable car. Indeed, the entire building becomes a disposable one. The Drytech Tank not only allows maintenance: it makes it practicable quickly and minimally invasive. Not only the wheel can be replaced: it can be done while the car is in motion, without interrupting the journey.

Out of metaphor, the theme of the maintainability of any waterproofing system is as fundamental as it is underestimated. Theoretically, any system works. In the real world there are unexpected events – very predictable – and the wear and tear of time.

The need and method of a maintenance system is sanctioned by the SIA Standard 260 : 2013:

2.3.4 Waterproofing: Underground structures inaccessible once the works are completed.

It’a mandatory to choose Waterproofing systems that allow maintenance from the internal side of the structure.

The ratio between the waterproofing cost must be 1 : <1 (for example: waterproofing 1000 : maintenance <1000).

The Drytech Tank always allows the waterproofing to be restored, through practical injections of DRYflex expansive resin from the inside of the work.

Being a single structure, in the Drytech Tank the cause and effect of any infiltrations coincide, so the intervention is timely and immediately verifiable with the naked eye. And it does not require the suspension of the building’s activities. Also for this reason Drytech maintenance systems are also used in the restoration of any other type of waterproofing.

Many systems offer waterproofing of the structure. But it is only the maintenance – actually practicable and non-invasive – that guarantees impermeability over time.