For the waterproofing of an underground wine cellar, a total Drytech Tank was built, as the roof is also covered by the vineyard.

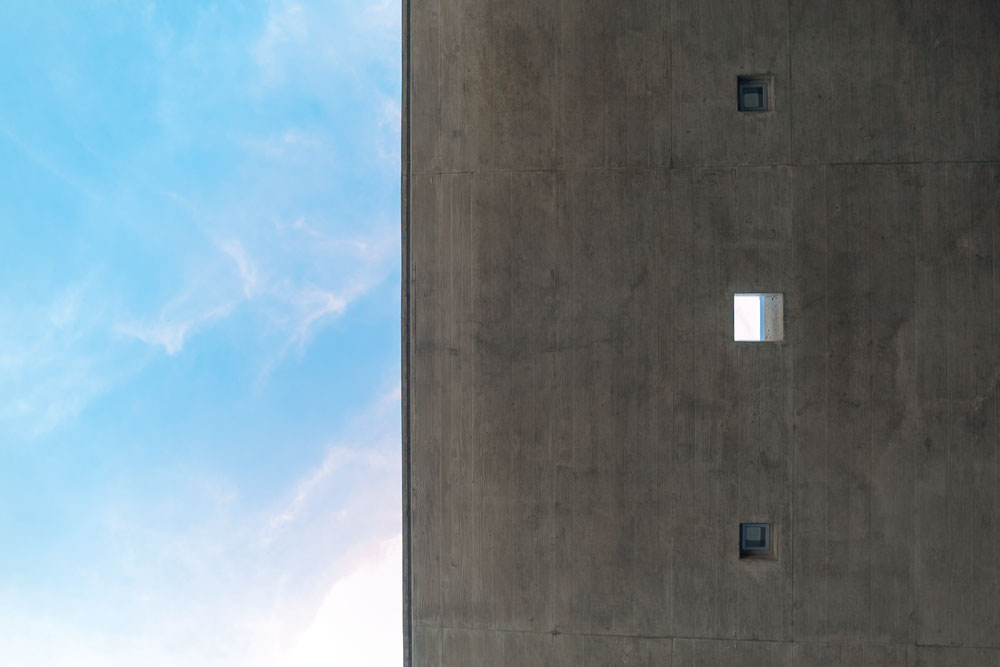

The new Giusti Wine cellar in Nervesa della Battaglia was designed by architect Armando Guizzo to tell a story of ties with the territory and harmony with nature.

Ermenegildo Giusti is a convinced supporter of viticulture that respects the environment and people. Giusti wanted a winery that plastically expressed the values of sustainability and integration.

The cellar is two thirds underground, while the emerged part integrates with the territory, not only architecturally but actually: the undulating roof with its rows is not an aesthetic exercise, but rather an authentic wine-growing area, structured to support the weight of the agricultural vehicles and which produces bunches exactly like the surrounding rows.

Particular attention was paid to the roofing, with an in-depth study of the materials used for growing the vines. First of all, the natural soil that covered the area before the construction site was excavated was restored on the roof.

Below this original soil, several layers of different natural materials were laid, including expanded clay, which in addition to ensuring the growth of the vines, make an important contribution to the energy saving of the building.

The entire hypogeum was created with a single waterproof Drytech Tank.

Owner: Giusti Dal Col, Nervesa della Battaglia

Project: Architect Armando Guizzo, Montebelluna

Structure: Engineer Alessandro Pagnan, Montebelluna

Drytech Tank: 4,500 m2