Waterproofing a hydroelectric power station built on the banks of the Po River with the Drytech Tank watertight structure.

Building for water can sometimes mean having to build underwater too. The new Casale Monferrato hydroelectric power plant was built below the left bank of the Po, and the river also completely flooded the construction site during the 18 months in which the work was carried out.

The natural flooding in the floodplain area where the construction site was opened did not represent a problem for the Drytech Tank, because the construction characteristics and materials of the system cannot be altered by the presence of water, not even during construction.

The same DRYflex resin, which is injected into the construction details to seal them, is effective in the presence of water, even under pressure.

Built by Allara SpA of Casale Monferrato, the system consists of a mobile weir in the riverbed, an intake structure upstream of the weir from which the diversion canal begins which conveys the water to the central building which houses the groups of energy production and, downstream of this, the return channel into the riverbed.

The work is completed by two access ladders – one on each bank – for the ichthyofauna and the ramp for the passage of canoes.

The mobile barrier crosspiece, made up of a tubular structure in water-inflatable rubberized fabric, guarantees the diversion of the water flow to the lateral intake work of the left bank.

When the water level upstream reaches the maximum authorized level, the crossbar is depressed under the pressure of the water that overcomes it, avoiding flooding.

With its 200 meters of longitudinal development, it is the largest flexible dam in the world built with this technology.

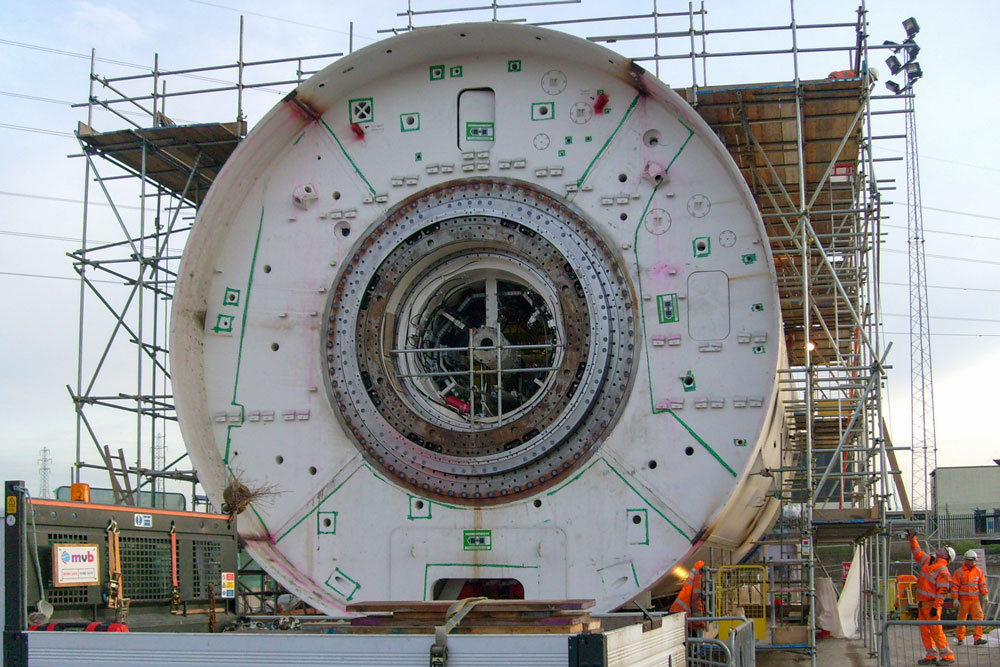

The production plant hosts four turbines that generate an average power of approximately 3000 kW, for an annual production of 21 GWh.

Access to the turbine room is guaranteed by an underground tunnel connected to an entrance hatch. The tunnel is also a full Drytech Tank (waterproof floor, walls and slab), connected to the main body by a movement joint which has been waterproofed with DRYset injectable Waterstop Tape.

Owner: Idropana, Turin

Technical direction: STA Engineering, Pinerolo

Structure: Eng. Gianluca Odetto – SERTECH, Loranzè

Construction: Allara SpA, Casale Monferrato

Drytech Tank: 1,200 m2