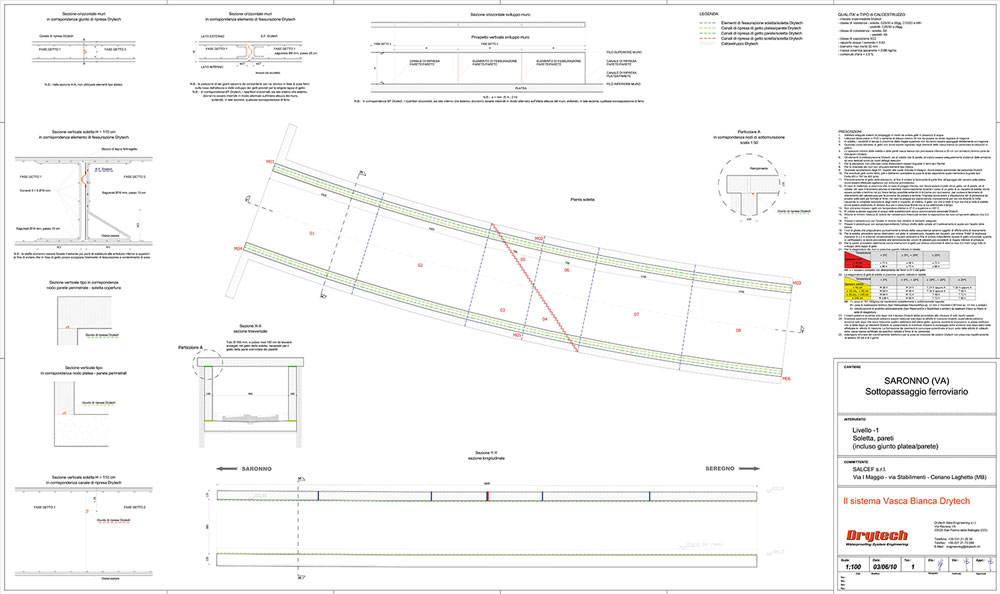

The waterproofing of a railway subway was achieved in just six days and without blocking train traffic thanks to the characteristics of the Drytech Tank.

The Trenord railway subway at Saronno is a demonstration of how one road can be opened without closing another.

The route of a new section of the Trenord railway intersects the Milan-Varese line at Saronno Sud.

The subway that allows the crossing was built in just six days and without interrupting the railway traffic on the line above.

The top-down or Berliner technique was adopted. First, micropiles were driven into the ground to form the bulkheads of the two shoulders of the subway. One section of track was removed, diverting traffic onto the other.

Then the excavation and casting of the Drytech waterproof concrete slab was carried out, supporting the bulkheads and prepared with DRYset crack control elements. The entire operation took only three days, at the end of which the track was restored.

The procedure was then repeated on the other track. After a further three days, the line returned to full operation, with both tracks open.

Excavation was then carried out under the slab, the casting of the slab for the track bed of the subway, and finally the re-cast, directly against the micropiles.

Once the concrete was cured, the joints, punctures and planned cracks were injected with DRYflex Resin, which expanded and sealed them by pressure.

Drytech Engineering provided advice on aspects relating to waterproofing, collaborating with the structural engineer already in the design phase of the underpass.

Ownership: Ferrovie Trenord, Milano

Structure: Studio I.R. Ingegneri Riuniti – Ing. Giuseppe Barbagallo, Catania

Constraction: SALCEF Spa, Roma

Drytech Tank: 1,800 m²